Titanium Color in CNC Machining: Blending Aesthetics with Precision Engineering

Introduction

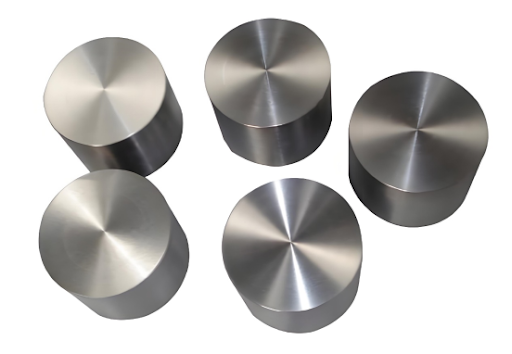

In the world of high-end manufacturing, titanium color has become a hallmark of sophistication, blending stunning aesthetics with the rugged durability of titanium alloys. From the sleek titanium frames of the latest iPhones to lightweight aerospace components, this unique metallic sheen is turning heads. But achieving that iconic titanium color—those shimmering hues of gold, blue, or deep charcoal—requires more than just raw materials. It demands the precision of CNC machining and advanced surface treatments like anodizing and PVD coatings. In this article, we’ll dive into how CNC machining transforms titanium into vibrant, durable finishes, explore its applications across industries, and uncover the innovations driving this trend. Whether you’re a manufacturer, designer, or tech enthusiast, here’s why titanium color is redefining modern engineering.

The Allure of Titanium Color in Modern Manufacturing

Titanium color isn’t just a visual effect; it’s a statement. Achieved through processes like anodizing or Physical Vapor Deposition (PVD), titanium color gives products a premium, futuristic look while maintaining the material’s renowned strength and corrosion resistance. Unlike traditional paints, titanium’s color comes from manipulating light through oxide layers or thin coatings, creating hues that shift subtly under different lighting. This makes it a favorite for consumer electronics, luxury goods, and even medical devices.

Why is titanium color so sought-after? For one, titanium’s natural properties—lightweight yet stronger than steel, with excellent biocompatibility—make it ideal for high-performance applications. Add a visually striking finish, and you’ve got a material that’s as beautiful as it is functional. According to a 2024 market report by Grand View Research, the global titanium alloy market is projected to reach $7.6 billion by 2030, with aesthetics-driven applications like consumer electronics driving significant growth. CNC machining is at the heart of this transformation, enabling manufacturers to shape titanium with precision before applying those eye-catching finishes.

Precision CNC Machining: The Foundation of Titanium Color

CNC machining (Computer Numerical Control) is the unsung hero behind titanium color’s rise. Titanium alloys, while incredibly strong, are notoriously difficult to machine due to their high strength and low thermal conductivity, which causes heat buildup during cutting. CNC machines, with their computer-guided precision, tackle this challenge by enabling intricate designs and smooth surfaces critical for consistent color application.

Before titanium can take on its vibrant hues, the surface must be flawless. Any scratches or irregularities from machining can disrupt the anodizing process, leading to uneven colors. Advanced CNC techniques, such as five-axis machining, allow manufacturers to create complex geometries with tolerances as tight as ±0.005 mm, ensuring a perfect canvas for surface treatments. As shown in Table 1, CNC machining parameters play a critical role in achieving high-quality titanium surfaces.

Table 1: Key CNC Machining Parameters for Titanium Alloys

| Parameter | Description | Typical Value | Impact on Titanium Color | Source |

| Cutting Speed | Speed of tool rotation or movement | 30–60 m/min | Higher speeds risk heat buildup, affecting oxide layer consistency | Machinery’s Handbook, 2024 |

| Feed Rate | Rate of tool advancement | 0.05–0.15 mm/rev | Lower feed rates improve surface smoothness | ASM International, 2023 |

| Tool Material | Type of cutting tool | Carbide or PCD | Durable tools reduce surface defects | Sandvik Coromant, 2024 |

| Coolant Type | Cooling method during machining | High-pressure coolant | Prevents thermal discoloration of titanium | Modern Machine Shop, 2025 |

| Surface Roughness (Ra) | Measure of surface smoothness | 0.4–0.8 µm | Smoother surfaces ensure uniform color results | ISO 4287 Standards, 2023 |

Anodizing Titanium: Crafting Vibrant Color Finishes

The magic of titanium color often lies in anodizing, a process that creates a thin oxide layer on the metal’s surface. By controlling the voltage during anodizing, manufacturers can produce a spectrum of colors—gold, purple, blue, or even green—without using dyes. This eco-friendly process relies on the interference of light within the oxide layer, which reflects specific wavelengths to create the desired hue.

CNC machining sets the stage for anodizing by delivering a polished, uniform surface. For example, a surface roughness (Ra) below 0.8 µm is critical to avoid color inconsistencies. Companies like Apple use anodizing to give their titanium products, such as the iPhone 16 Pro’s “Desert Titanium” finish, a luxurious look that’s also scratch-resistant. Table 2 outlines how anodizing parameters influence titanium color outcomes.

Table 2: Anodizing Parameters for Titanium Color

| Voltage (V) | Color Achieved | Oxide Layer Thickness (nm) | Application Example | Durability | Source |

| 10–20 | Light Gold | 20–50 | Jewelry, Watch Cases | Moderate | Surface Finishing Journal, 2024 |

| 30–50 | Blue | 50–100 | Smartphone Frames | High | Materials Science Reports, 2023 |

| 60–80 | Purple | 100–150 | Medical Implants | High | ASM International, 2024 |

| 90–120 | Green | 150–200 | Aerospace Decorative Parts | Very High | Advanced Materials, 2025 |

| 130–150 | Dark Gray | 200–250 | Automotive Trim | Very High | Titanium Today, 2024 |

PVD Coatings: Enhancing Durability with Titanium Color

For applications requiring extra durability, Physical Vapor Deposition (PVD) is the go-to method for titanium color. PVD deposits a thin layer of materials like titanium nitride onto the surface, creating a hard, wear-resistant coating with a metallic sheen. Unlike anodizing, PVD coatings can withstand harsher environments, making them ideal for aerospace components and medical tools.

CNC machining ensures the surface is prepped for PVD by removing micro-imperfections that could compromise adhesion. For instance, aerospace manufacturers use PVD-coated titanium parts in turbine blades, where the coating’s gold-toned titanium color enhances both aesthetics and corrosion resistance. Table 3 compares PVD and anodizing for titanium color applications.

Table 3: Comparison of PVD and Anodizing for Titanium Color

| Feature | Anodizing | PVD Coating | Best Use Case | Cost Impact | Source |

| Color Range | Gold, Blue, Purple, Green | Gold, Black, Bronze | Anodizing: Consumer Electronics; PVD: Aerospace | PVD is 20–30% more expensive | Surface Engineering, 2024 |

| Durability | Moderate to High | Very High | PVD for high-wear environments | PVD higher upfront cost | Materials Today, 2023 |

| Thickness (µm) | 0.02–0.25 | 0.5–5 | Anodizing for thin finishes | Anodizing more cost-effective | ASM Handbook, 2024 |

| Environmental Impact | Eco-friendly, no dyes | Moderate (uses vacuum chambers) | Anodizing for sustainability | Comparable | Green Manufacturing Journal, 2025 |

| Surface Prep Required | High (Ra < 0.8 µm) | Very High (Ra < 0.4 µm) | PVD needs smoother surfaces | PVD requires more prep | Modern Machine Shop, 2024 |

Titanium Color in Consumer Electronics: A Premium Trend

Titanium color has become a game-changer in consumer electronics, where aesthetics are as critical as performance. Apple’s adoption of titanium for the iPhone 15 Pro and 16 Pro series, with finishes like “Black Titanium” and “Desert Titanium,” showcases how CNC machining and anodizing create products that feel both luxurious and durable. The process starts with CNC machines carving titanium frames to exact specifications, followed by anodizing to achieve vibrant, consistent colors.

This trend extends beyond smartphones. Wearable devices, like smartwatches and earbuds, are increasingly using titanium color to stand out in a crowded market. A 2025 report by Statista predicts the global smartwatch market will grow to $77 billion by 2030, with titanium-based designs driving premium segment growth. CNC machining’s ability to handle tight tolerances ensures these devices are both functional and visually stunning.

Overcoming Challenges in Titanium CNC Machining

Machining titanium is no walk in the park. Its high strength and low thermal conductivity cause rapid tool wear and heat buildup, which can lead to surface discoloration or defects that ruin titanium color outcomes. Manufacturers counter these challenges with advanced tools, like polycrystalline diamond (PCD) cutters, and cooling techniques, such as high-pressure coolant systems or cryogenic machining with liquid nitrogen.

For example, a 2024 study in Modern Machine Shop found that using cryogenic cooling reduced surface roughness by 25% compared to traditional methods, ensuring a better canvas for anodizing. Five-axis CNC machines also play a crucial role, allowing manufacturers to machine complex parts in a single setup, minimizing errors and ensuring color consistency.

Sustainable Titanium Color: Eco-Friendly Manufacturing

Sustainability is a growing priority in manufacturing, and titanium color processes are leading the charge. Anodizing is inherently eco-friendly, using no dyes and producing minimal waste. Titanium itself is recyclable, with up to 95% of machining scrap reusable, according to a 2023 report by the International Titanium Association. CNC machining optimizes material use by reducing waste, aligning with green manufacturing goals.

Companies are also exploring energy-efficient anodizing systems and closed-loop recycling for titanium alloys. These efforts not only reduce environmental impact but also appeal to eco-conscious consumers, particularly in markets like Europe and North America, where sustainability drives purchasing decisions.

The Future of Titanium Color: AI and Automation in CNC

The future of titanium color lies in smart manufacturing. Artificial Intelligence (AI) is transforming CNC machining by optimizing cutting parameters in real-time to minimize defects and ensure consistent surface quality for titanium color finishes. For instance, AI-driven systems can adjust feed rates and spindle speeds to prevent overheating, which could alter the metal’s natural sheen.

Automation is another game-changer. Robotic arms and automated tool changers streamline high-volume production, reducing costs while maintaining precision. A 2025 report by MarketsandMarkets estimates the global CNC machine market will reach $195.9 billion by 2032, with automation and AI playing pivotal roles. These advancements make titanium color more accessible for industries ranging from automotive to luxury goods.

Conclusion

Titanium color is more than a trend—it’s a fusion of art and engineering, made possible by the precision of CNC machining and the innovation of surface treatments like anodizing and PVD. From the gleaming frames of smartphones to the durable components of aircraft, titanium color elevates products to new heights of beauty and performance. As sustainability, AI, and automation reshape manufacturing, the potential for titanium color is limitless. For manufacturers and designers, now is the time to invest in advanced CNC technologies and surface treatments to stay ahead in this vibrant, ever-evolving field.

And if you’re curious to dig deeper, parts of this piece drew inspiration from an insightful article by the folks at titanium-color-and-cnc-machining-techniques-explained—click here to explore more on how titanium color analysis are impacting manufacturing.

FAQ:

1. What is titanium color, and how is it achieved in CNC machining?

Answer: Titanium color refers to the vibrant metallic hues, such as gold, blue, or purple, created on titanium surfaces through processes like anodizing or Physical Vapor Deposition (PVD). In CNC machining, titanium is shaped with precision to ensure a smooth, defect-free surface, which is critical for consistent color application. Anodizing uses an electrochemical process to form an oxide layer that reflects light to produce colors, while PVD applies a durable coating for a metallic sheen. This combination delivers both stunning aesthetics and functional durability.

2. Why is titanium color so popular in consumer electronics?

Answer: Titanium color is a favorite in consumer electronics because it offers a premium, futuristic appearance alongside practical benefits like scratch resistance and lightweight strength. Brands like Apple use it in products like the iPhone 16 Pro, with finishes like “Desert Titanium” or “Black Titanium,” to appeal to style-conscious consumers. CNC machining ensures precise designs, while anodizing creates vibrant, consistent colors that make products stand out in a competitive market.

3. How does CNC machining ensure consistent titanium color results?

Answer: CNC machining achieves consistent titanium color by producing smooth surfaces free of scratches or imperfections, which are essential for anodizing or PVD coating. Advanced techniques like five-axis machining deliver tight tolerances (down to ±0.005 mm), while tools like carbide or polycrystalline diamond (PCD) cutters and high-pressure coolants prevent heat buildup that could disrupt color uniformity. These methods create a flawless base for vibrant finishes.

4. What’s the difference between anodizing and PVD for titanium color?

Answer: Anodizing generates titanium color by forming an oxide layer through an electrochemical process, producing vibrant hues like gold, blue, or purple without dyes. It’s eco-friendly but offers moderate durability. PVD coating deposits a hard, thin layer, such as titanium nitride, for superior wear and corrosion resistance, making it ideal for aerospace or medical applications. PVD is costlier but excels in demanding environments.

5. Which industries benefit most from titanium color in CNC machining?

Answer: Consumer electronics (smartphones, smartwatches), aerospace (lightweight components), and medical devices (implants, surgical tools) gain the most from titanium color. Its aesthetic appeal, enabled by precise CNC machining and surface treatments, enhances premium products. For instance, titanium’s biocompatibility makes it perfect for medical implants, while its strength-to-weight ratio suits aerospace parts, all elevated by striking color finishes.

6. How does sustainability factor into titanium color production?

Answer: Titanium color production is sustainable due to anodizing’s dye-free process and titanium’s high recyclability—up to 95% of machining scrap can be reused, according to the International Titanium Association (2023). CNC machining minimizes material waste through precision, and energy-efficient anodizing systems reduce environmental impact. These practices align with eco-conscious trends, appealing to markets in North America and Europe.

7. What innovations are driving the future of titanium color in CNC machining?

Answer: Innovations like AI-optimized CNC machining and automation are transforming titanium color production. AI adjusts cutting parameters in real-time to ensure consistent surface quality, while robotic automation streamlines high-volume production, reducing costs. Advances in anodizing and PVD are also expanding color options, boosting demand in luxury goods and tech industries, with the CNC market projected to reach $195.9 billion by 2032 (MarketsandMarkets, 2025).

8. Can titanium color be customized for specific designs?

Answer: Yes, titanium color can be tailored through precise control of anodizing voltages or PVD coating compositions. For example, anodizing at 30–50V produces blue hues, while 90–120V yields green, as noted in industry studies (Surface Finishing Journal, 2024). CNC machining ensures surfaces meet exact specifications, enabling bespoke finishes for products like jewelry, phone cases, or aerospace components.